Fix It Together: The Power of Community Repair

Getting Started with Local Repair Gatherings

Finding a Nearby Meetup

Start by checking community calendars at libraries, makerspaces, and neighborhood centers, then browse international directories listing repair cafés and fix-it clinics. Ask hardware stores and recycling depots, too. Many groups rotate venues, so review schedules, join a mailing list, and volunteer to receive early announcements.

What to Bring and How to Prepare

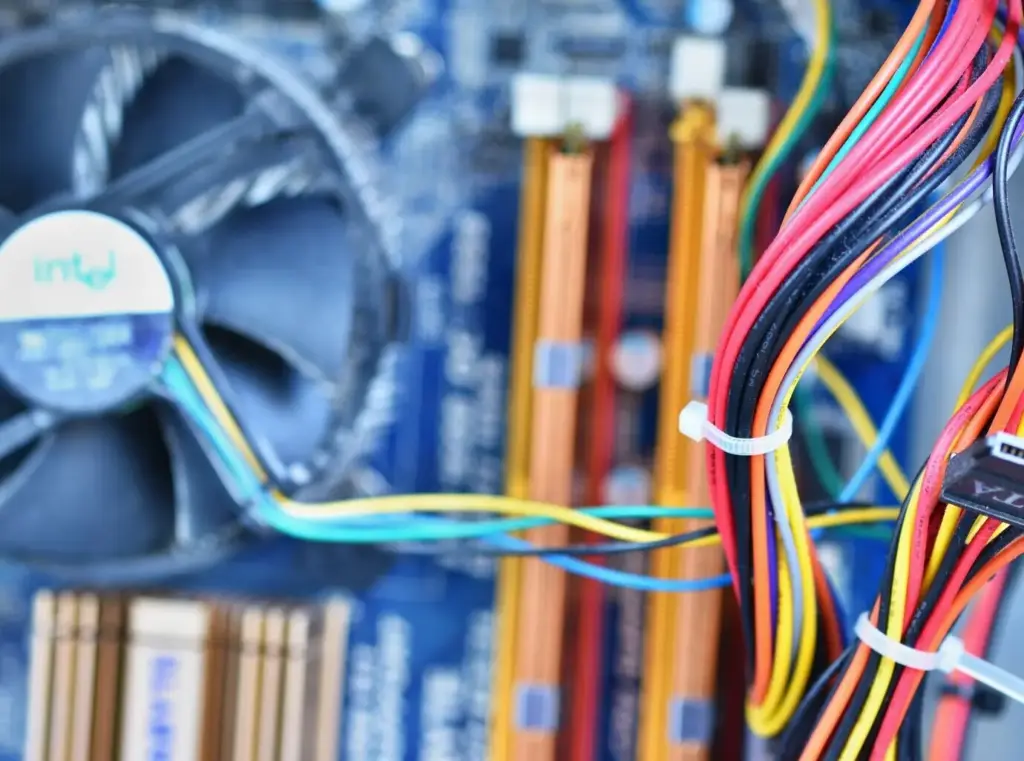

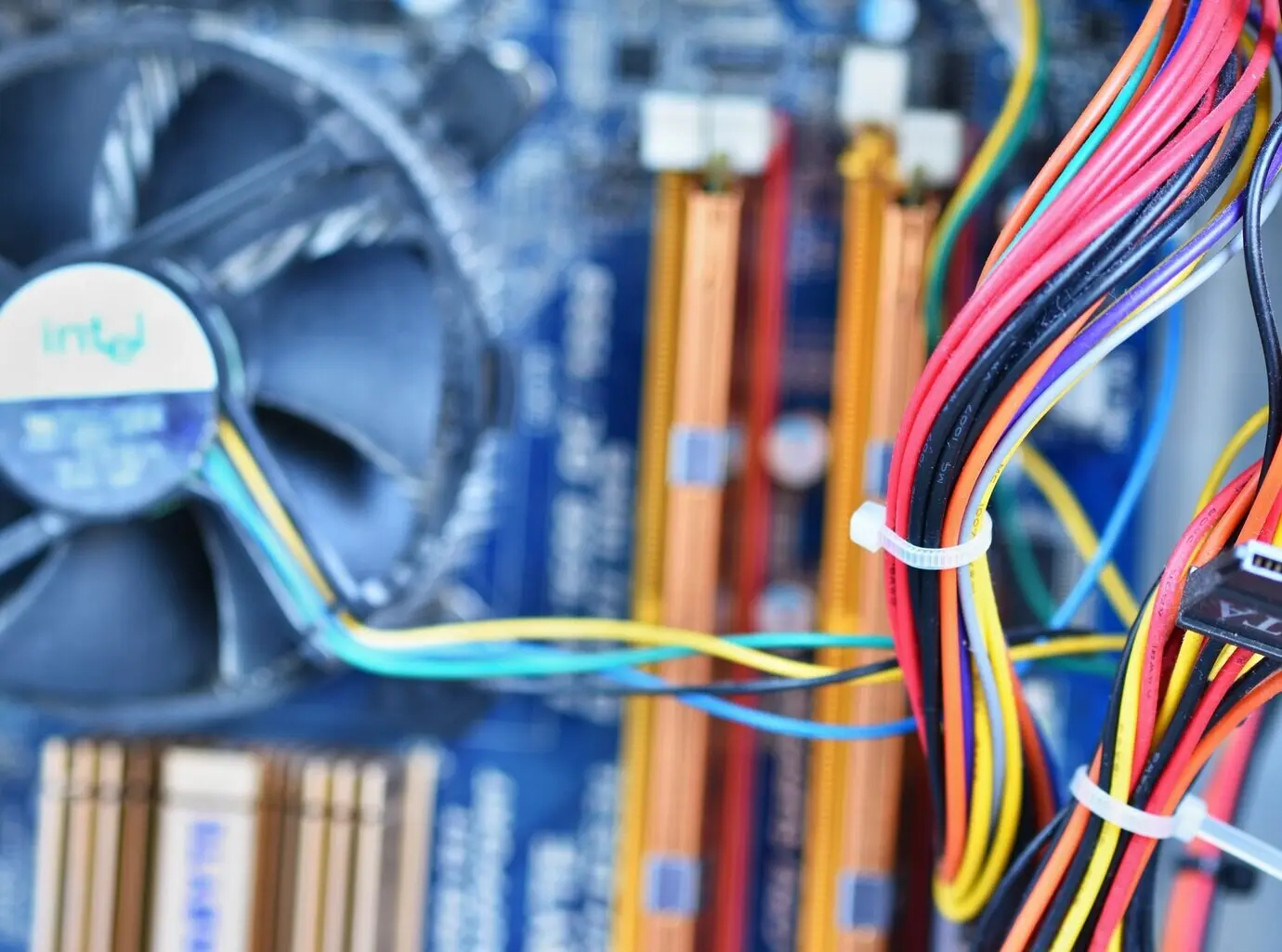

Bring the item itself, its power adapter, batteries, screws or bolts, and any packaging or manuals you still have. Photograph labels and model numbers. Clean the item, note symptoms, back up data if electronic, and transport it safely in a box or padded bag.

Understanding Safety and Triage

Upon arrival, a triage volunteer listens, records details, and checks for obvious hazards. Safety matters: mains voltage, damaged cords, blades, and swollen batteries require caution and sometimes refusal. Expect sign-in forms, shared benches, eye protection, and friendly explanations before decisions about repair approaches begin.

Starter Toolkit for Most Homes

Adhesives, Lubricants, and Fasteners

Spares and Sourcing Parts Responsibly

Repair Stories that Inspire Confidence

From Curious Visitor to Confident Fixer

Start with observation, asking why each test is chosen and which risks are ruled out. Next, handle tools under supervision, practicing cable stripping, basic soldering, and screw extraction. Keep a notebook of wins and failures, and soon you will guide newcomers with humility.

Workshops and Micro-Lessons

Short, focused sessions—like diagnosing power issues, repairing zippers, or understanding adhesives—build momentum without overwhelming beginners. Rotate instructors, incorporate hands-on practice, and end with reflection. Publish slides and checklists afterward so attendees can revisit concepts and help at the next gathering with growing confidence.

Documenting Repairs to Teach Others

Photos, part numbers, wiring notes, and outcomes create a trail that demystifies the process for newcomers. Share documentation in searchable folders and community forums. Tag models, common faults, and safety cautions. Clear records reduce repeated mistakes and help measure impact over months and years.

Waste Avoided, Carbon Saved

Neighborhood Connections that Last

Advocacy and the Right to Repair

Finding Resources, Directories, and Support

Planning Checklist and Roles

Welcoming Culture and Accessibility

All Rights Reserved.